Tesla ensures every vehicle meets stringent factory specifications through a meticulous multi-step painting process that combines advanced technology and skilled craftsmanship. Beginning with thorough body preparation and ending with rigorous inspection, each layer of paint adheres to precise thickness and quality standards. Post-production checks and regular owner maintenance are vital to protect the pristine exterior and maintain Tesla's commitment to delivering superior vehicles.

“Uncover the meticulous craftsmanship behind Tesla’s iconic finishes. This article delves into the intriguing world of Tesla factory specifications for paint thickness and finish, revealing the standards that set their vehicles apart. From understanding precise measurement techniques to exploring the intricate processes ensuring an impeccable final touch, we unveil the secrets. Additionally, we provide essential maintenance tips to preserve the durability and pristine condition of your Tesla’s breathtaking finish, reflecting the brand’s commitment to quality.”

- Understanding Tesla's Paint Thickness Standards

- The Process of Achieving Specified Finish Quality

- Ensuring Longevity: Post-Production Checks and Maintenance Tips

Understanding Tesla's Paint Thickness Standards

Tesla’s commitment to quality is evident in their stringent factory specifications for paint thickness and finish. The company prides itself on delivering vehicles with a flawless exterior that not only looks stunning but also offers superior protection for the car bodywork. These standards are meticulously maintained throughout the production process, ensuring every Tesla rolled off the line meets the highest industry benchmarks.

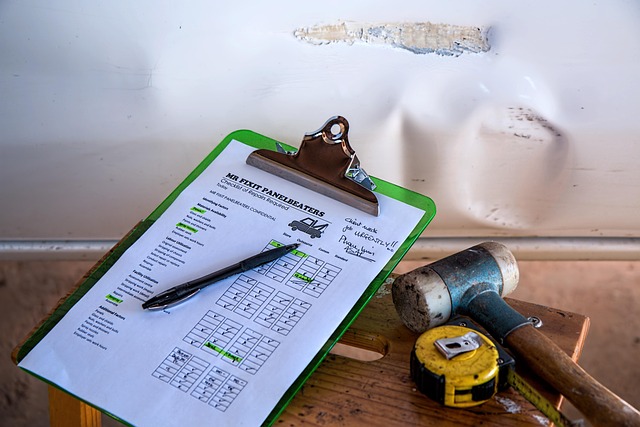

The attention to detail starts with precise frame straightening techniques employed by the vehicle body shop. This foundational step ensures the structural integrity and flatness of the car’s frame, which is crucial for achieving consistent paint thickness. Once the frame is perfect, a multi-step painting process begins, incorporating advanced technologies and high-quality materials to create a durable and glossy finish that not only enhances the car’s aesthetics but also protects it from environmental factors.

The Process of Achieving Specified Finish Quality

Achieving the meticulous finish standards set by Tesla factory specifications involves a rigorous process that combines advanced technology and skilled craftsmanship. It begins with precise preparation of the vehicle body, which includes thorough cleaning, degreasing, and surface treatment to ensure optimal adhesion for the paint layer. This foundational step is crucial in ensuring the durability and longevity of the final finish.

Once the vehicle body is ready, a multi-stage painting process takes over. This involves applying primer, base coat, and clear coat layers, each carefully formulated to meet Tesla’s stringent thickness and quality standards. Specialized equipment, like robotic paint applicators, ensures consistent and precise coating, minimizing human error. After application, each layer undergoes careful inspection for any defects or inconsistencies before proceeding to the next stage, guaranteeing a flawless finish that matches the brand’s high-quality benchmarks.

Ensuring Longevity: Post-Production Checks and Maintenance Tips

Ensuring Longevity: Post-Production Checks and Maintenance Tips

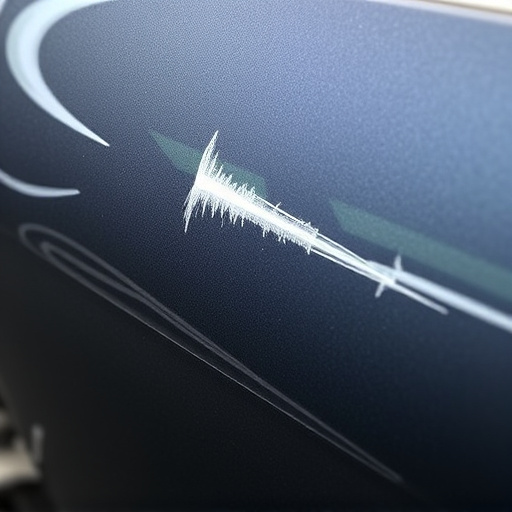

After rolling off the production line, Tesla vehicles undergo rigorous quality control checks, including meticulous inspections of paint thickness and finish as per Tesla factory specifications. This step is vital to guarantee the durability and pristine condition of the vehicle’s exterior for years to come. Any deviations from the Tesla factory standards during manufacturing or subsequent transport can be addressed promptly by trained technicians. Regular post-production assessments play a crucial role in identifying potential issues early on, whether it’s a slight imperfection or signs of damage incurred during car collision repair processes.

To maintain the optimal finish and protect against future car damage repair needs, Tesla owners should familiarize themselves with best practices. This includes periodic checks for signs of wear and tear, prompt addressing of chips or scratches in the paint, and regular washing using approved methods to prevent damaging the vehicle’s delicate exterior. By adhering to these guidelines, Tesla owners can ensure their vehicles not only meet the high standards set by the factory but also remain in top condition, minimizing the need for extensive vehicle body shop repairs down the line.

Tesla’s commitment to exceptional paint quality is evident through its stringent factory specifications, ensuring a durable and pristine finish on every vehicle. By implementing rigorous processes and post-production checks, Tesla maintains its reputation for delivering top-tier finishes that meet exacting standards. Understanding these specifications is key to appreciating the craftsmanship behind each Tesla, as well as providing owners with essential maintenance tips to preserve their vehicle’s lustrous appearance over time.